Harness The Power Of Air...

Tired of using a traditional Mixing Stick? Well... we've got a super simple tip that could help save you time and ensure greater consistency with your finished metal coatings.

We often get asked by our customers, if we have any useful tips or bits of advice we can share to help them make the most out of range of metal coatings.

So, we've decided to publish a series of useful tips that can help you to make the most out of our coatings and achieve some great results.

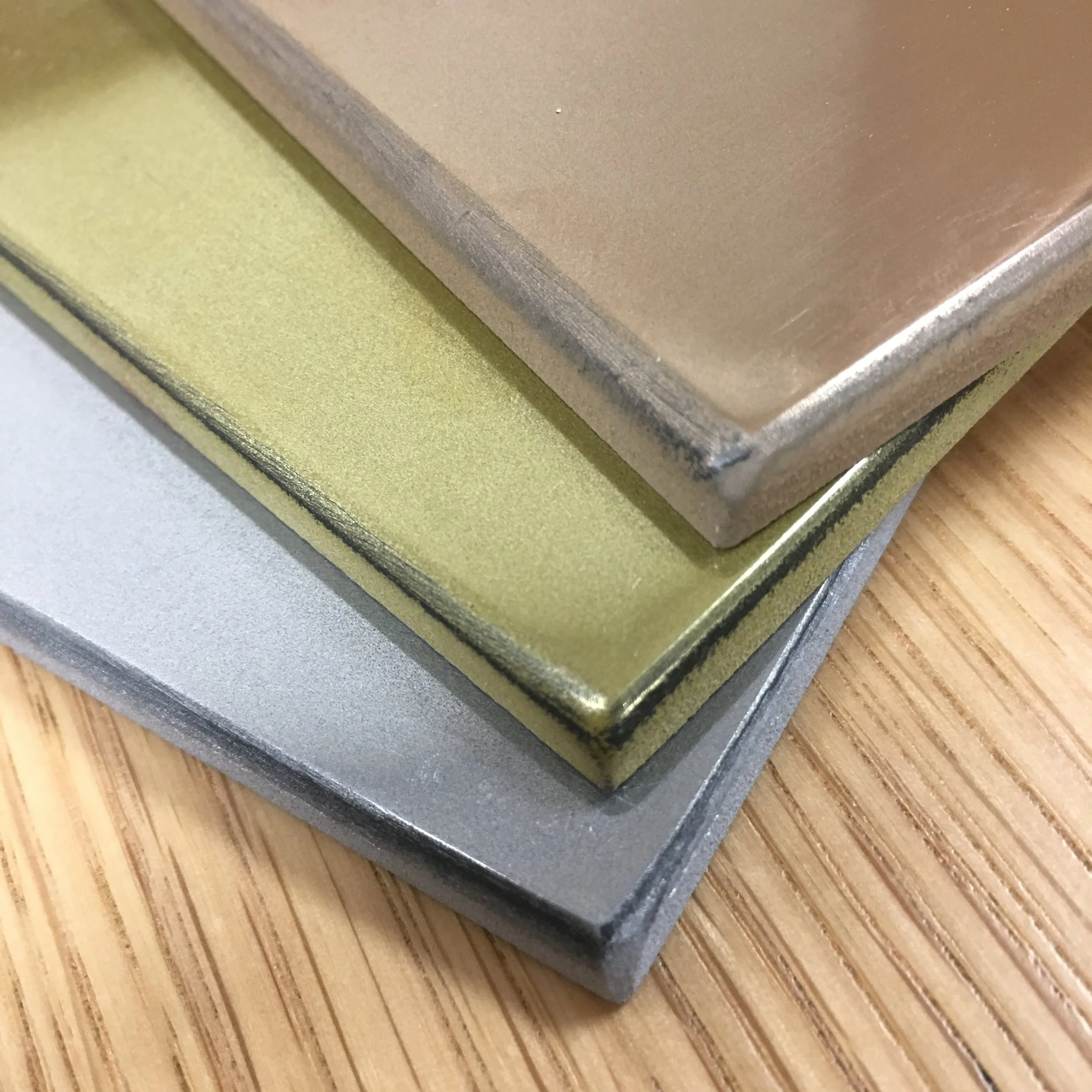

Today, we wanted to share with you how we are able to produce samples each day and end up with a consistent coating of metal that looks great and shows off what you can do with our products. The secret... Air Power!

When using the traditional method of mixing together the components that go into our products, often our customers use a mixing stick. Mixing our products that way is totally fine and often works well, but if you are keen to get a smooth, consistent coating of your chosen metal on your chosen surface, we recommend using an Air Drill with a whisk attachment. By utilising this method, you can make sure the mix is blended well so you don't have to worry about any part of the solution not being bound together properly.

This can help you save time, money and more importantly stress! Working with Liquid Metal Coatings can be tricky, but it doesn't have to be... that's why we started Liqui-Met, to make Metal Coatings that are easy to use, offer great results and are cost effective.

If you enjoyed this post, be sure to check back in each week as we post new articles with top tips, product releases and much more.